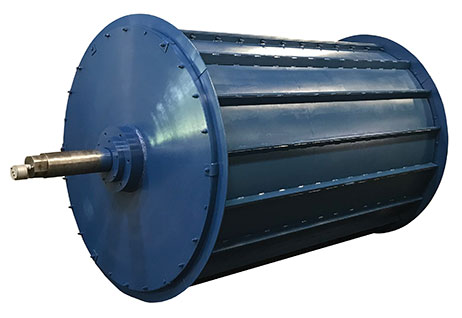

Stearns Magnetic Drums

Stearns Magnetic Drums are designed to improve efficiency in handling heavy volumes of large size material encountered in today’s scrap and slag processing and mineral concentration applications. The drum consists of an electromagnet assembly mounted inside an outer rotating drum assembly. The magnet assembly position, although stationary during operation, may be adjusted within certain limits to meet varying feed arrangements.

- Heavy duty manganese steel cylinders and knock-offs provide extended service life

- Axial or radial pole design allows for more efficient ferrous material separation from burden

- Heavy duty manganese steel cylinders and knockoffs provide extended service life

- Application specific bearing arrangements and knock-offs available

- Optional field replaceable wear covers

- Custom engineered shafts to meet all interface requirements

- Standard sizes ranging from 30” to 72” (762 to 1830 mm) in diameter and up to 110” (2795 mm) in length

Features

- LDA high-performance design offers a uniform, magnetic field across the full working width of the drum

- Superior deep field design

- Heavy duty manganese steel cylinders with knockoffs

- Rugged weatherproof construction

- Side shields bolted to the drumhead

- 2-piece, heavy duty split-wear covers available

- Various knock-off pattern options

- Permanent magnet designs available

- Coil construction produces a concentrated deep magnetic field to maximize ferrous recovery

Applications

- Scrap shredding

- Slag reclamation

- Tramp iron removal

- Ore cobbing

LITERATURE

Stearns Solutions for Ferrous Material Separation Catalog

TECHNICAL SPECIFICATION TABLES

Stearns Electromagnetic Drums LD-Radial Design

Stearns Electromagnetic Drums LDA-Axial Design